18 May Overhead Protection Systems

Sealing underground bins and voids with Overhead Protection Systems

Improving safety and reducing hazardous work in underground mining is paramount to the longevity of the mining industry. M2P Engineering’s Overhead Protection Systems are designed to enhance site safety whilst increasing efficiency.

It is common practice to use Bosun’s Chairs and other types of fall protection to suspend personnel into underground voids, allowing them to undertake work such as maintenance on the walls of the void, maintenance on machinery deployed in the void, or to prime the walls of the void before commencing work underneath.

These labour-intensive jobs have a plethora of inherent hazards which pose major risk to personnel and equipment. Hazards such as working at heights, use of equipment which is not fit for purpose, possible dropped objects – both above and below the suspended worker, interactions with other workers, and interactions with vehicles. Some of the risks include entanglement, suspension trauma, as well as the potential to fall from height.

The Queensland Government has issued safety alerts about the dangers of using Bosun’s Chairs and other types of fall prevention devices, however, suggestions to decrease risks include employing safety fall nets, which don’t eliminate fall risk.

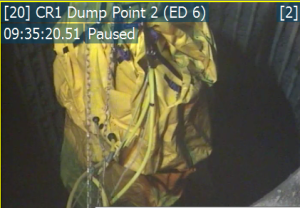

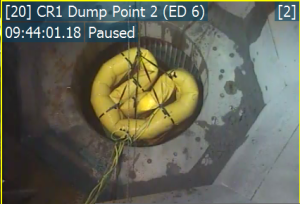

Taking an innovative approach, M2P Engineering has developed an inflatable PVC Overhead Protection System (OPS) which is designed to be inserted into these voids, eliminating the need for unnecessary dangerous work.

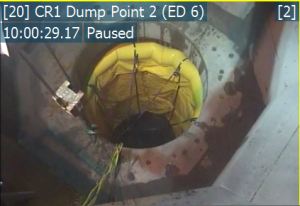

These heavy-duty, reusable, balloon-like devices are manufactured to fit the void and inflate to create pressure against its sides, limiting the potential for rock fall and object fall. M2P’s Overhead Protection Systems are fitted with pneumatic control systems, which are operated from a safe distance.

By utilising M2P’s Overhead Protection Systems it is possible to mitigate the risk to personnel and equipment, and drastically reduce the time required to prepare the void before works can commence beneath it.

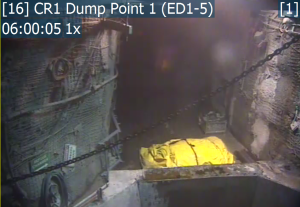

See an example of an inflatable overhead protection system installation below – this installation took just 3 hours from starting site preparation, to workers entering the zone under the bin. Previously the risks were controlled by cleaning down the bin using a Bosun’s Chair. As described above, this process is dangerous and could take as long as 12-24 hours depending on the condition of the bin.

Contact us to discuss how M2P can engineer a solution for you.